Solar Roadway® panels are made of tempered (safety) glass. Glass was chosen for its hardness, strength, durability, and transmittance.

SR glass is textured to create proper traction for vehicles and pedestrians. The glass passed traction tests, load tests, and impact resistance tests at university civil engineering labs around the country.

Each unit is made of top and bottom glass panels, with the other components such as solar cells and LED lights enclosed between. One major difference one will notice when comparing SR glass panels to traditional asphalt roads is aesthetics. The hexagonal panels are quite a work of art and will dramatically beautify roads, parking lots, walkways, patios, bike paths, etc.

Solar Roadways® chose the hexagonal shape for extra stability to wear and flexibility in installing curves, hills, and odd shaped installations. There are half and quarter panel shapes as well. Eventually, other shapes will be added to the SR catalogue of options.

Unlike asphalt, SR panels are impervious to potholes. The repair of potholes is an enormous expense, source of danger and an unnecessary inconvenience to motorists.

The glass has undergone both 3D Finite Element Method analysis and actual physical load testing at civil engineering labs. The results showed that Solar Roadways can handle trucks up to 250,000lbs (113,398kg). Originally, it was thought that Solar Roadways® panels would need to support only about 80,000lbs (36,287kg), the maximum legal limit for a semi-truck. Upon further research, it became apparent that since logging trucks have no scales in the woods, that can be exceeded. The goal was then adjusted to 150,000lbs. It was subsequently learned that oil companies can get permission to move refinery equipment up to 230,000lbs on frozen roads, so the goal was increased to 250,000lbs.

Some have asked if the current limit of 250,000lbs would support a tank. The current M1A2 Abrams tank weighs about 68 tons, or 136,000lbs, which is well within the current limit.

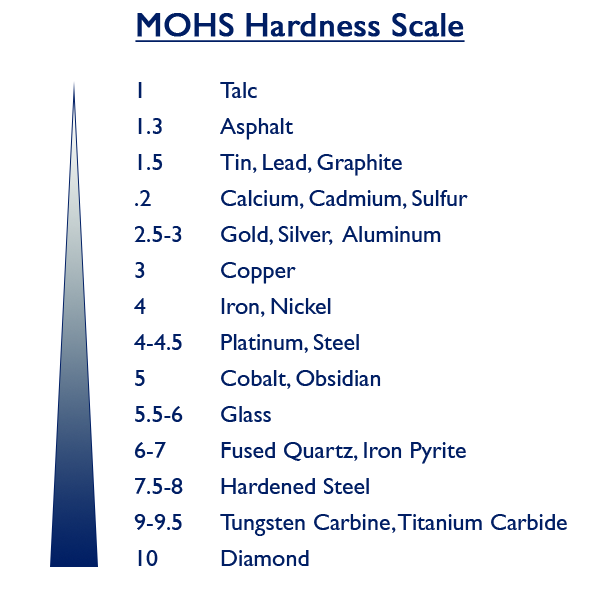

The scale to measure the hardness of materials is called the Mohs hardness scale. It refers to the resistance of a material to being scratched. It lists materials from the softest to the hardest e.g., on a 1 to 10 scale, with talc earning a 1 and diamond, (the hardest common material) being 10.

Asphalt has a hardness of 1.3, copper has a hardness of 3, iron and nickel have a hardness of 4, and steel falls between 4 and 4.5. As you move up the scale closer to diamond, you finally come to glass, which has a hardness of 5.5-6.0.

When glass is tempered it becomes four to five times stronger than the non-tempered annealed glass listed in Mohs hardness scale. Tempering does not make the glass harder - just stronger. Bulletproof and bomb (blast) resistant glass is made with tempered glass. Solar Roadway® Panels are manufactured in a similar manner. Tempered glass is less likely to experience a thermal break.

One of the many technical specs required for SR panels is for a glass surface textured to provide the same or greater traction than current asphalt roads offer (at a minimum) - even in the rain. A variety of textures were tested with a British Pendulum Skid Resistance Tester. Some did not provide enough traction, and one had such an aggressive texture it broke off a piece of the tester. The SR2 texture used was a midrange texture. The final testing results showed the texture was sufficient to stop a vehicle going 80mph (129kph) on a wet surface in the required distance. The test results apply to motorcycles and bicycles as well. New textures will be tested, and the long term goal is to have a whole catalog of textures available to perfectly match each application. For example, highways will require the most robust texture. Applications that are primarily used by pedestrians such as sidewalks and plazas will want a less aggressive texture.

Currently, SR panels can be made with two different types of surfaces:

SR panels have been designed to last a minimum of 20 years. The advanced loading test that will be performed during Phase IIB will simulate many years of truck abuse in a matter of months. Environmental testing will also be performed. All of this will help to maximize the life expectancy of the SR panels. Solar cells are the limiting factor: they can continue to work up to 30 years but they are at the end of their life cycle by then.

The hexagonal shape was chosen so that any force from vehicles (such as during a collision) is distributed to multiple surrounding panels. The small hexagonal shapes also allow for easier installation on hills and curves.

Since the Solar Roadways® system is modular, repair will be much quicker and easier than the current maintenance system for asphalt roads. In the U.S. the time Americans spend idling in traffic costs the nation in a variety of ways.

From the American Automobile Association:

“While many Americans experience congestion on a daily basis, few realize that every hour of congestion, delay, and lack of reliability adds a cost to most services and goods produced or consumed in America.”

Apparently the problem is becoming more serious over time. The new 2015 Urban Mobility Scorecard reports that:

“America’s traffic congestion recession is over. Just as the U.S. economy has regained nearly all of the 9 million jobs lost during the downturn, a new report produced by INRIX and the Texas A&M Transportation Institute (TTI) shows that traffic congestion has returned to pre-recession levels.

According to the 2015 Urban Mobility Scorecard, travel delays due to traffic congestion caused drivers to waste more than 3 billion gallons of fuel and kept travelers stuck in their cars for nearly 7 billion extra hours – 42 hours per rush-hour commuter. The total nationwide price tag: $160 billion, or $960 per commuter.

Washington, D.C. tops the list of gridlock-plagued cities, with 82 hours of delay per commuter, followed by Los Angeles (80 hours), San Francisco (78 hours), New York (74 hours), and San Jose (67 hours).

The problem has become so bad in major urban areas that drivers have to plan more than twice as much travel time as they would need to arrive on time in light traffic just to account for the effects of irregular delays such as bad weather, collisions, and construction zones. For example, drivers on America’s Top 10 worst roads waste on average 84 hours or 3.5 days a year on average in gridlock – twice the national average. Of these roads, six are in Los Angeles, two are in New York and the remaining two are in Chicago. Nine other cities have roads ranked among the 50 worst.”

Each of the SR panels contain their own microprocessor, which communicates wirelessly with surrounding panels. If one of them should become damaged it would stop communicating, and the surrounding panels can report the problem. For instance, "I-95 mile marker 114.3 northbound lane, third panel in, panel number A013C419 not responding".

The panels are light enough that a single operator could load a functioning panel into his/her truck and take it to the location of the damaged panel. The panel could be swapped out and reprogrammed in a few minutes. The damaged panel would then be returned to a repair center.

Potholes are a major source of repair need for asphalt roads and the repair is not nearly as quick or efficient. Potholes in asphalt are formed when moisture accumulates in cracks and breaks in the structure of the asphalt. Temperature fluctuations leading to freezing and thawing then cause expansion and contraction of the material, causing it to weaken. The weight of vehicles contributes to the problem further and eventually a pothole forms. This process cannot happen with SR panels since they are completely impervious to water and therefore potholes will become a thing of the past.

Potholes and other types of road damage can be a danger to drivers, motorcyclists, cyclists, pedestrians, and vehicles. Sometimes potholes are disguised when covered with a puddle of water or ice. Sudden potholes can startle drivers. Some may try to swerve to miss them, which can lead to accidents.

AAA has discussed damages that potholes can do to vehicles. They report that hitting a pothole can knock wheels out of alignment, which then affects steering. A hard impact can dislodge wheel weights, damage tires and wheels, and even suspension components. More about potholes from AAA can be found here.

People may wonder how SR panels can be installed on hills and curves and how they can accommodate the typical 3% crown that roads have. The very first SR prototype was 12ft x 12ft – it was quickly realized that that size would have made such sites difficult to tackle.

Two important changes were made. The panels were shrunk to about 4ft2 and the shape was changed to hexagons, partially because it was apparent that those changes would make installing on hills and curves so much easier. Roads have what are known as “crowns”: the middle of the road is the highest point so that stormwater doesn’t puddle, but instead runs off of the road. The hexagons easily cover this gentle 3-percent slope.

Eventually, it’s expected that a variety of shapes and sizes will be added to the Solar Roadways® catalog, offering even greater flexibility.

There is also a concern how much a layer of dirt would interfere with solar gain if it did not wash off.

A unique test was conducted during summer drought conditions when the surroundings were covered in dirt/dust. There are two identical traditional (not SR) solar panels positioned on the roof of the original SR lab. For the experiment, only one of them was kept clean and then the outputs were compared.

After one of the panels was cleaned, their performance was monitored throughout a sunny summer day. The clean panel only produced 9% more power than the dirt covered panel. Worst case senario, if it is determined that it is difficult to keep the panels clean, it may only result in a small energy loss. Another consideration is that SR panels, being on the ground, are much easier for homeowners to clean than rooftop panels.

Some anecdotal data was collected with the prototype parking lot: a rubber soled shoe and a bike tire were used to scuff a section of concrete and a section of the SR glass. The rubber on the glass came off with the simple wipe of a finger: it didn't stick well to the glass. That was not the case with the porous concrete: the skid marks were very hard to remove due to the porous nature of concrete.

The supposition is that the simple act of tires rolling over a skid mark on the glass will be enough to loosen the material, which will then blow off or be removed the next time it rains.

It is apparent that most roads with high speed vehicles keep themselves quite clean. Most small particles are blown off by the passing vehicles, with the exception of spills from oil, transmission fluid, etc.

A possible solution for those substances is a common natural compound called titanium dioxide(TiO2). Consultation with a manufacturer revealed that titanium dioxide turns substances like oil and grease into a powder, that would be blown off by wind or washed away by rain. It is currently used on building facades to keep them clean. One manufacturer reported to SR that roads sprayed with titanium dioxide only needs to have it reapplied every few years.

The worst case scenario would be the following: if there is a significant problem with keeping roads clean and all of the above solutions fail, street sweepers may be employed where needed (vehicles with large rotating brushes). They are used in Idaho in the spring to clear the roads of the sand that was used for traction during the winter months.

People ask how would a Solar Roadway® glass panel be likely to fair in the event of various disasters?

It’s to be expected that any force that could destroy an asphalt or concrete road (e.g., an earthquake, sinkhole, or landslide) would have a similar result with a Solar Roadway®. Power will not be lost however: only the damaged panels will stop producing, while any nearby panels that are intact would continue to produce power.

Another advantage of Solar Roadways® in regard to such disasters is their ability to double as an early warning system to alert residents of an impending hurricane, tornado, or the like. The road lines could flash in a particular color (to be determined by DOT officials) so that drivers would know to immediately check local weather reports and avoid danger zones.

Similarly, the roads could create detours and redirect residents away from areas of danger, into safe areas. Most lanes of a highway could be repurposed to take drivers to safety, with perhaps one lane continuing to the danger zone for EMS personnel. Solar Roadways® anticipates consultations with earthquake scientists to see if embedded sensors in some SR panels might aid in data collection and prediction.

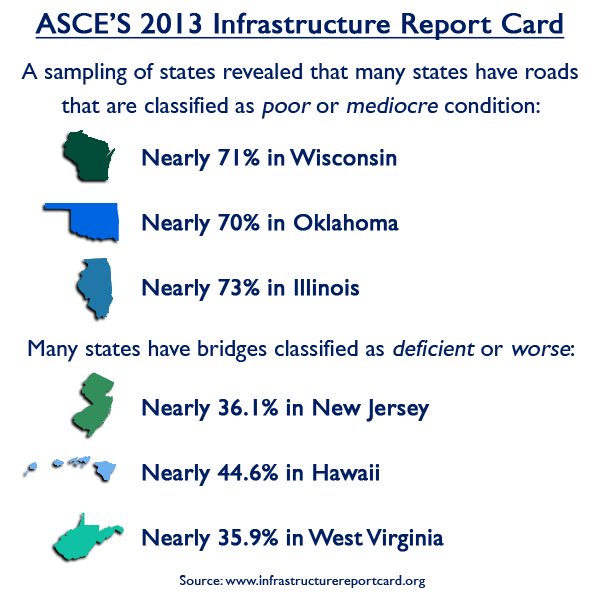

The White House website presents a wealth of useful information to help understand the current U.S. infrastructure crisis: “The U.S. lags behind many of its overseas competitors in transportation infrastructure investment. In the most recent World Economic Forum rankings, the U.S. had in less than a decade fallen from 7th to 18th overall in the quality of our roads. 65 percent of America’s major roads are rated in less than good condition, one in four bridges require significant repair or cannot handle today’s traffic, and forty-five percent of Americans lack access to transit.”

They describe the effects of this problem vividly:

“The costs of inadequate infrastructure investment are exhibited all around us. Americans spend 5.5 billion hours in traffic each year, costing families more than $120 billion in extra fuel and lost time. American businesses pay $27 billion a year in extra freight transportation costs, increasing shipping delays and raising prices on everyday products. Underinvestment impacts safety too. There were more than 33,000 traffic fatalities last year alone and roadway conditions are a significant factor in approximately one-third of traffic fatalities. Such fatalities occur disproportionately in rural America, in part because of inadequate road conditions.”

The problem stems from a lack of funding, as state DOTs allotments continue to fall short of the funds needed to build new roads and maintain current roads each year. Supporters write that sometimes their state DOTs have let asphalt roads return to gravel and gravel roads return to dirt, as they just are not able to maintain them.

Some states such as Missouri have begun to think outside the box. MoDOT is exploring the building of a high tech "Road to Tomorrow", which can showcase possibilities for modern infrastructure. They have approached Solar Roadways® about the possibility of using SR panels as part of this project. Consultation is ongoing.

The modular glass panels created by Solar Roadways® can provide a way to have a modular, intelligent, durable, and modern highway system. This system can offset its initial cost over time by the generation of clean renewable energy (link to Solar Energy page here), helping to eliminate many of the described problems. Thousands of American jobs could be created, while Americans work together to create an infrastructure to be proud of. The same can be true for every country as SR moves to respond to interest.